The underground mining industry has traditionally been labor-intensive, hazardous, and environmentally challenging. However, advancements in intelligent control systems are revolutionizing mining operations, making them more efficient, safer, and sustainable. This article explores the application scenarios of intelligent control systems, how the new 5G control systems improve mining efficiency, and the enhancement of mining efficiency and reliability.

Application Scenarios of Intelligent Control Systems

Intelligent control systems are increasingly being integrated into various facets of underground mining operations. These advanced systems utilize machine learning, artificial intelligence (AI), and Internet of Things (IoT) technologies to optimize processes, enhance safety, and reduce operational costs. Here are some key application scenarios:

Automated Mining Equipment

One of the most notable applications is the automation of mining equipment. Autonomous vehicles, including haul trucks, loaders, and drills, can now navigate the labyrinthine underground mines with minimal human intervention. These vehicles are equipped with sensors, cameras, and GPS systems that allow them to operate efficiently and safely, even in challenging environments.

Real-time Monitoring and Data Analysis

Intelligent control systems enable real-time monitoring of mining operations. Sensors placed throughout the mine collect data on variables such as temperature, humidity, air quality, and equipment status. Advanced data analytics tools process this information to provide actionable insights, facilitating quick decision-making. This capability is crucial for detecting anomalies, predicting equipment failures, and preventing accidents.

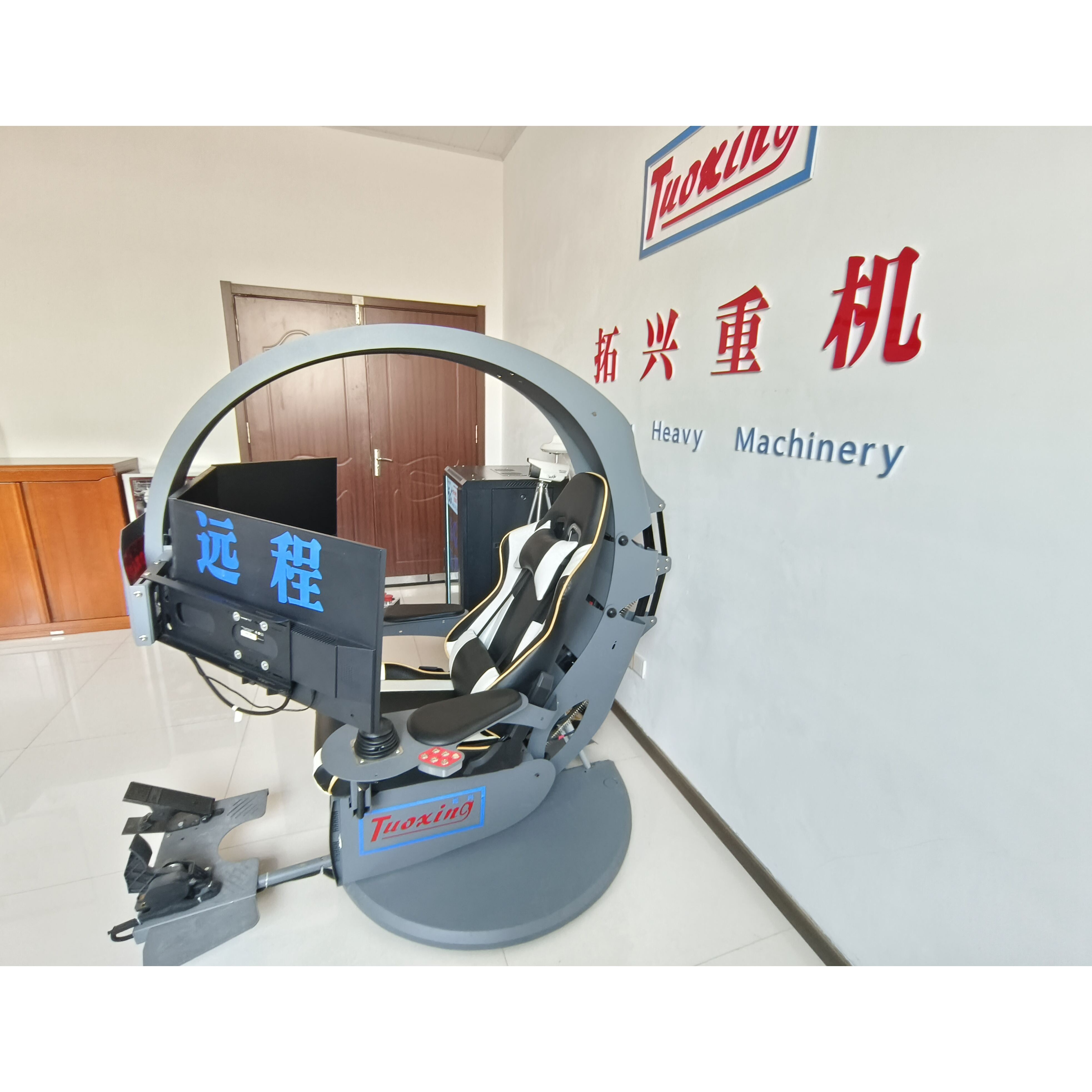

Remote Control and Supervision

With intelligent control systems, miners can control and supervise equipment remotely, reducing the need for on-site presence in hazardous conditions. This remote accessibility is especially beneficial in underground mining, where safety concerns are paramount. Operators can control machinery from safe locations, minimizing the risk of accidents and improving overall safety.

Predictive Maintenance

Predictive maintenance is another critical application of intelligent control systems. By analyzing data from equipment sensors, these systems can predict when a machine is likely to fail or require maintenance. This proactive approach prevents unexpected breakdowns, reduces downtime, and extends the lifespan of mining equipment.

Improvement of Mining Efficiency by New 5G Control Systems

The advent of 5G technology is set to further revolutionize the underground mining industry. The high-speed, low-latency capabilities of 5G networks provide a robust foundation for intelligent control systems, enabling real-time communication and data exchange.

Enhanced Connectivity

5G technology offers enhanced connectivity, even in the challenging environment of underground mines. This improved connectivity is vital for the seamless operation of autonomous equipment and real-time monitoring systems. With 5G, large volumes of data can be transmitted quickly and reliably, ensuring that mining operations remain efficient and responsive.

Real-time Data Processing

The low latency of 5G networks allows for real-time data processing. Intelligent control systems can process and analyze data in near real-time, providing immediate feedback and enabling prompt decision-making. This capability is essential for optimizing operations, reducing downtime, and enhancing overall productivity.

Improved Safety Protocols

The integration of 5G technology enhances safety protocols in underground mining. With real-time monitoring and data analysis, potential hazards can be identified and addressed promptly. Additionally, 5G-enabled communication systems ensure that workers can maintain constant communication, further improving safety and coordination.

Improvement of Mining Efficiency and Reliability

The implementation of intelligent control systems has a profound impact on both the efficiency and reliability of mining operations.

Optimized Resource Utilization

Intelligent control systems optimize the utilization of resources, including energy, equipment, and labor. Automated equipment operates with precision, reducing waste and maximizing productivity. Real-time monitoring and predictive maintenance ensure that machinery operates at peak efficiency, minimizing downtime and extending equipment life.

Reduced Environmental Impact

The efficiency gains from intelligent control systems also translate to reduced environmental impact. By optimizing resource use and minimizing waste, these systems contribute to more sustainable mining practices. Additionally, the ability to monitor environmental conditions in real-time helps ensure compliance with regulatory standards and minimizes the impact on surrounding ecosystems.

Improved Reliability

Reliability is critical in mining operations, where equipment failures can lead to costly delays and safety risks. Intelligent control systems enhance reliability through predictive maintenance and real-time monitoring. By identifying potential issues before they become critical, these systems help prevent unexpected breakdowns and ensure continuous operation.

Enhanced Decision-Making

Intelligent control systems provide valuable insights that enhance decision-making. With access to real-time data and advanced analytics, mining operators can make informed decisions that improve operational efficiency and safety. This data-driven approach enables continuous improvement and adaptation to changing conditions.

In conclusion, intelligent control systems are reshaping the underground mining industry by enhancing efficiency, safety, and reliability. The integration of 5G technology further amplifies these benefits, enabling real-time data processing and improved connectivity. As these technologies continue to evolve, the future of underground mining looks brighter, safer, and more sustainable.

Table of Contents

- Application Scenarios of Intelligent Control Systems

- Automated Mining Equipment

- Real-time Monitoring and Data Analysis

- Remote Control and Supervision

- Predictive Maintenance

- Improvement of Mining Efficiency by New 5G Control Systems

- Enhanced Connectivity

- Real-time Data Processing

- Improved Safety Protocols

- Improvement of Mining Efficiency and Reliability

- Optimized Resource Utilization

- Reduced Environmental Impact

- Improved Reliability

- Enhanced Decision-Making

EN

EN

AR

AR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

UK

UK

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

BE

BE

HY

HY

KA

KA

EO

EO

LA

LA

SO

SO

ZU

ZU

KK

KK

TG

TG

UZ

UZ

KY

KY

XH

XH