call us

+86-18561032768mail us

[email protected]call us

+86-18561032768mail us

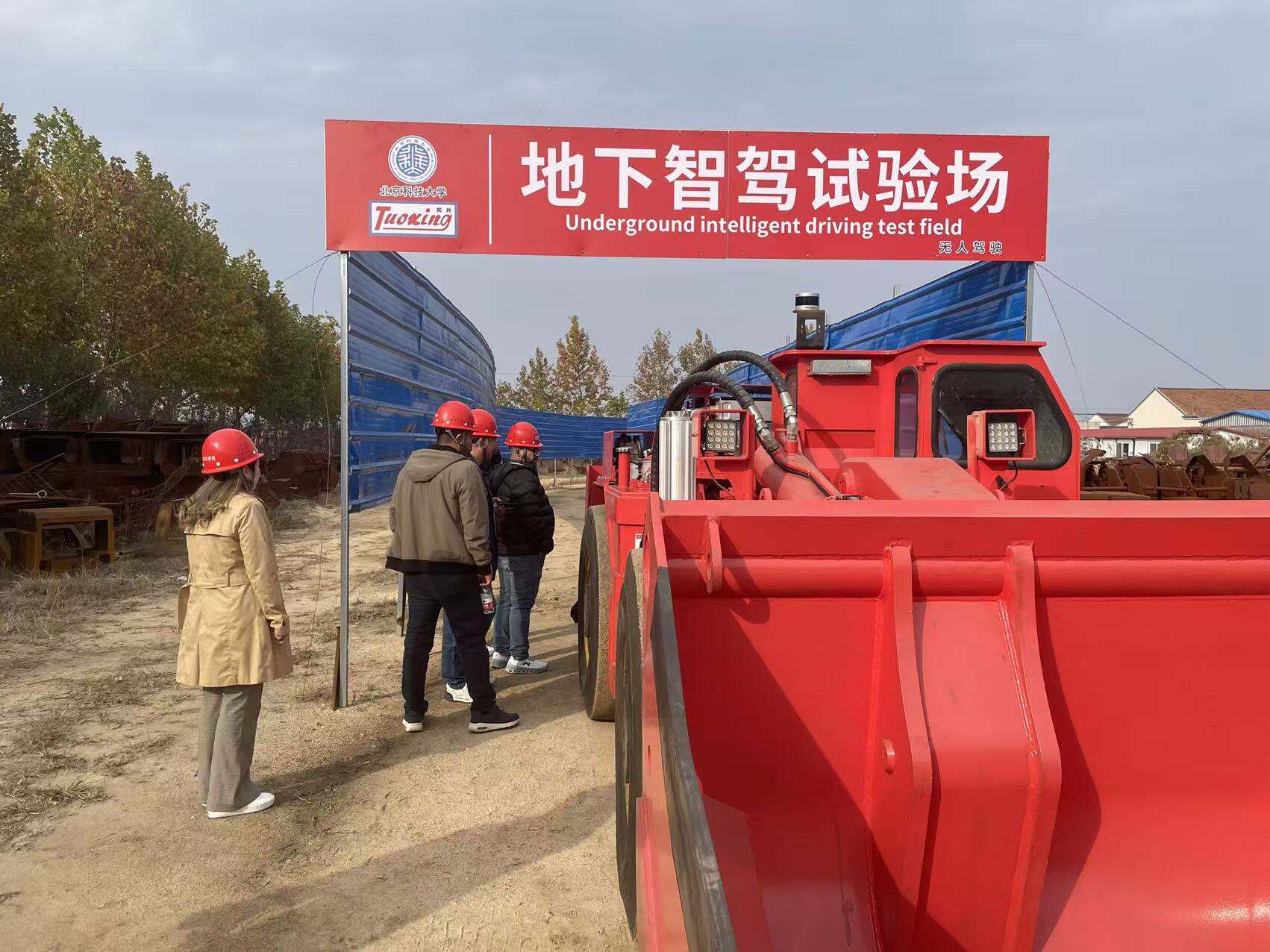

[email protected]In late December 2025, a delegation of executives and technical experts from a prominent Mexican mining company conducted a dedicated three-day inspection and exchange at Tuoxing Heavy Industry in China. The visit served to evaluate Tuoxing’s three-decade legacy in underground mining equipment, focusing on how its solutions could be tailored to enhance operational efficiency and safety within Mexico's diverse and challenging geological conditions.

Core Inspection Highlights and Key Advantages

The program extended beyond a standard facility tour, centering on in-depth technical dialogues about performance, quality, and customization.

Full-Process Manufacturing and Quality Control

The delegation toured core production zones, observing the complete manufacturing process for underground trucks and LHDs, from cutting and welding to final assembly. Particular attention was given to stress-relief techniques and non-destructive testing for critical components like frames and buckets. The modular assembly lines and rigorous testing protocols—including simulated slope traction and hydraulic sealing tests—visibly demonstrated Tuoxing’s commitment to reliability in extreme operating environments.

Customized Design for Specific Scenarios

Addressing the client's noted challenges of high altitude, dust, and narrow veins, Tuoxing engineers presented targeted solutions. These included optional high-altitude turbocharged engines, enhanced air filtration systems, and compact articulated designs for improved maneuverability. A live demonstration of an underground side-excavator highlighted its unique lateral digging capability, offering a practical solution for confined working faces and earning strong appreciation from the delegates.

Deepening Cooperation: From Product to Service Partnership

The discussions naturally progressed from equipment specifications to comprehensive lifecycle support, establishing a foundation for sustained collaboration.

Data-Backed Performance and Support

Tuoxing substantiated its commitments with operational data from global mine sites. For instance, performance metrics for a flagship underground loader model showed a roughly 25% increase in Mean Time Between Failures (MTBF), attributed to core system optimizations. The company outlined its dedicated rapid-response service network in Latin America, plans for localized spare parts inventory, and remote diagnostic support—all aimed at minimizing client downtime.

Outcome and Future Perspective

Complementing the technical agenda, traditional Chinese hospitality facilitated a warm atmosphere for relationship-building. The delegation leader remarked, "We have witnessed a partner that translates deep experience into reliable quality and genuinely listens to solve our specific challenges. This is about forging a strategic partnership." The visit successfully conveyed Tuoxing Heavy Industry's expertise, customer-centric adaptability, and commitment to global partnership, marking a significant step toward collaborative ventures in the Americas market.