call us

+86-18561032768mail us

[email protected]call us

+86-18561032768mail us

[email protected]Mining Trucks: The Innovations that Keep Mines Running

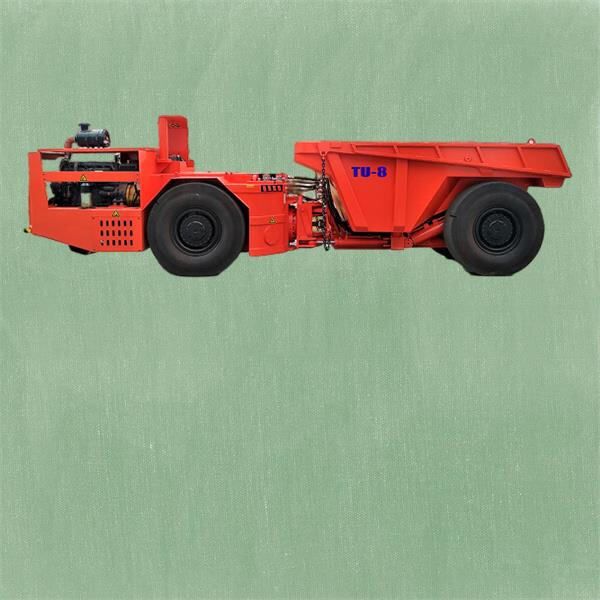

In today's realm, mining is conducted on a massive scale the assistance of machines and equipment so that resources can be removed at a much faster rate, just like the Tuoxing's product called underground articulated truck. Being an essential element, mining trucks play a pivotal role transporting natural resources through the mine site to the processing plant. We will delve into mining truck, their advantages, innovations, safety procedures, utilize, and how to use them to offer a more in-depth understanding of this robust machine.

Mining trucks have become a tasks part integral of their numerous advantages over other mining equipment, also the coal mine loader built by Tuoxing. First, they can carry large quantities of minerals, metals, or coal in a single trip increasing productivity and reducing the time taken for transportation between the mine site and processing flowers. This decreases functional costs improves the company's ability to maintain margins, and ensure business continuity eventually. Second, they are highly durable, allowing them to operate for extended periods of time and in harsh environments without the need for frequent maintenance.

Innovation is the cornerstone of modern mining technology, the same as Tuoxing's underground mining utility vehicles. The design of mining trucks has evolved significantly, with numerous innovations that have led to improved safety and performance over the years. Night for example, the introduction of autonomous mining trucks has revolutionized the industry by allowing mining companies to operate at without risking the safety of workers. Additionally, the integration of hybrid technologies in the newest models of mining trucks has enabled companies to minimize fuel usage, reduce carbon emissions and reduced maintenance costs.

Mining truck safety procedures are essential to the mining industry's continued success, as well as the machines used in underground mining supplied by Tuoxing. The security of mining trucks is a top priority requires careful consideration of factors such as driver training, accident prevention, and maintenance of safety equipment. Accidents involving mining trucks can be devastating, considering their size and weight. As a total result companies have implemented safety procedures such as speed restrictions, prevention of overloading, and maintenance schedules that allow for timely interventions.

Mining trucks come in various sizes, from small trucks capable of carrying a few tons massive models capable of carrying up to 400 tons, just like the Tuoxing's product called truck underground. The type of mining truck used is dependent on the mine site's specific needs, the distance become traveled, and the sort of terrain. Small mining trucks are useful in areas where terrain is flat, and the distance between the mine and processing plant is short, while large models are suitable for longer distances or terrain. mining trucks hilly can be used for many purposes, such as carrying raw materials from the mine site, carrying waste to disposal sites, and transporting equipment and personnel.

All of technical us of is composed of experienced engineers who've worked in underground Mining trucksfor over three decades. Our engineers can be found to simply help our clients in most circumstances it doesn't matter if it's for research and development manufacturing, after-sales support or production.

Our experienced engineering team effective at providing professional services to the clients. We could provide the best mechanical equipment customers can utilize in underground Mining trucks, based on their requirements of the dimensions, variety of ore, and annual output of mines.

Tuoxing Machinery has been in existence for more than twenty years. Our focus has been on underground Mining trucksproducts as well as machinery. Be a the main customer-centric approach continue to develop our products in response to your feedback and connection with our customers. We only have the charged capacity to do what our customers expect.

Our factory covers a place of 266000 square meters includes a full production that include welding of steel plates, profile processing Mining trucks, assembly. Therefore, us to produce, or perhaps the customer requesting us to examine and develop production, we could match the customer's needs whether it's the client supplying drawings want. We additionally have professional suppliers for transmissions, engines, and axles, such as Deutz, DANA, Kessler, Benz, and Volvo.

Mining trucks are made for certain purposes and are extremely specialized machines, the same as scoop tram created by Tuoxing. To work them correctly, it is important to have proper training certification. Operators must have knowledge of the truck's settings, security features, and handling requirements. Protection training is essential to make sure that operators understand their role in preventing accidents and keeping on their own and other people safe in their jobs.

Mining trucks require regular maintenance and repairs to safely make sure they run and efficiently, just like the Tuoxing's product called load and haul in mining. High-quality solutions are crucial for keeping the lifespan of mining trucks. To ensure top-notch solution, mining companies should select qualified technicians with extensive knowledge of mining trucks. Routine maintenance such as oil changes, tire rotation, and brake replacement should be carried out according to the manufacturer's specifications.

Mining trucks have a broad application the mining industry, same with the load haul dumper produced by Tuoxing. They have been primarily used in surface mining, where minerals are extracted linked to the ground, and in the quarrying process, where materials are extracted from semi-solid substances like rocks and sand. mining trucks are also used in open-pit mining operations—these are surface mines where open pits dug to extract minerals from the earth. Large mining trucks are also used in mountain mining, where minerals are removed from high-altitude locations.